The 9-Minute Rule for Spandrel Glazing Panel

Table of ContentsWhat Does Glazed Spandrel Construction Mean?Indicators on Spandrel Glazing Definition You Should KnowGet This Report about Spandrel Glazing PanelSpandrel Glazing Panel Things To Know Before You BuyThe 8-Second Trick For Viracon Spandrel GlazingNot known Incorrect Statements About Spandrel Glazing

When using spandrel glass, moir can happen when a pattern's darkness is cast versus the spandrel glass. The moir pattern is not a defect in the glass or spandrel process but rather a pattern developed by the eye. For added information, please review.are consisted of a protected glass system with an opacifier put on with an opacifier related to either the # 3 or # 4 surface of the interior glass lite. To ensure a constant general visual, it is advised you utilize the exact same low-e layer on your vision glass and also you insulated spandrel systems.

If a low-e coating is positioned on the # 2 surface as well as an opacifier on surface area # 3, compatibility of the opacifier as well as sealer, as well as the prospective release of volatiles into the air area need to be verified with Vitrum Glass group. It is essential to keep in mind, using low-e coated glass together with a tool to dark pacifier will boost the temperature of the unit, resulting in raised levels of thermal tension.

The Best Guide To Spandrel Glazing Panels

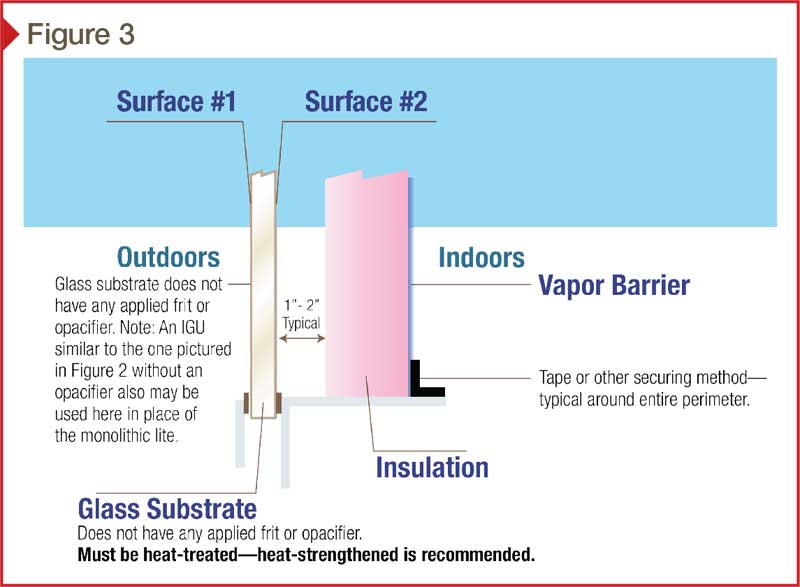

Darkness box describing need to also ensure that surfaces of the glazing system and surrounding materials have a dark surface area to avoid read-through under some illumination problems. includes a lite of covered or uncoated glass with an opacifier on surface area # 2. Insulation can be utilized by directly using it to the opacifier layer. spandrel glazing panels.

In multi-story structures the areas between floorings, where building elements are held, is called spandrel. When a structure has a full glass exterior with a seamless look, the glass covering the spandrel areas is referred to as spandrel glass. Spandrel glass has both indoor and outside applications, though spandrel glass used on the outside of a structure normally is heat treated as well as protected, to guarantee it offers the buildings similar to that which an actual wall would supply.

Spandrel glass frequently is additionally reflective, which aids it to mask the area behind it.

4 Simple Techniques For Spandrel Glazing Units

non-heat-treated) or fully tempered glass to continue to be in position till it can be replaced. Whether heat-strengthened or totally solidified, heat-treated glass products are produced in a similar style and making use of the exact same processing tools. The glass is heated to approximately 650 C (1200 F), after that force-cooled to develop surface and also edge compression.

As shown in Figure 1, insulation is commonly made use of combined with spandrel glass - spandrel glazing panel. When the insulation is to be applied straight to the opacified surface of the spandrel glass, it is vital to work with a glass spandrel fabricator, as well as the adhesive as well as insulation distributors, to make sure these items work with the opacifying product.

Opaque glazing, steel panels, MCM (steel composite materials) panels, or protected laminated panels are commonly made use of as spandrel infill. When insulation is used inboard of the spandrel infill, an air room is consistently introduced to stop thermal damage to the spandrel infill. Sadly, the air room can give a chance for condensation to develop on the indoor face of the spandrel infill.

10 Easy Facts About Glazing Spandrel Panel Detail Shown

Along with wetness damage as well as microbial growth, condensation growth on spandrel infill can likewise have a negative result. Also if the glazing system is resistant to water seepage from outside, condensation and also wetness can still establish on the spandrel infill. This dampness can be absorbed by the bordering components, causing damages to the setting up as well as nearby surface areas.

By increasing airflow near these places, more warmth link will certainly be moved to the assembly as well as rise interior surface area temperatures. An additional method to use the HEATING AND COOLING system is by lowering the inside relative humidity set factors with regard to outside temperature. By reducing the amount of readily available wetness, condensation development as well as possible buildup can be postponed.

The Basic Principles Of Black Spandrel Glazing

Something failed. Wait a minute and attempt once more Try once again.

Structural Basics Words "spandrel" is a building term that describes an archway or other crested system of supports. Spandrel glass is just one of the only kinds of glass qualified of covering this sort of framework in a manner that not only fits its curvature, however likewise produces the impression of a single as well as unbroken wall surface.

Some Known Factual Statements About Spandrel Glazing Panels

Treatment these with glass glazing glass facade can frequently create an even more pleasing, brightened appearance than would certainly filling them in or constructing an extra typical wall over them. This kind of glass tends to be nontransparent, and also is generally reflective. Occasionally individuals can see out of it, but most of the times it actually wards off light and often shows up to have a mirrored surface.

Visual High Qualities Among the most valued facets of this material is its capacity to develop an overall consistent appearance. The glass is frequently colored, and because of this it can match most various other sorts of glass that are used to develop a building front. Environment-friendly and also blue shades often tend to be a few of the most typical, as these have the ability to reflect the sky with certain precision.